Aligner Manufacturing Solutions

Precision systems covering every step of modern aligner production.

- Automatic trimline detection & PTS export for laser cutting

- Separator bar generation on the dental arch

- ID-based file assignment for fully automated LAC cutting

- Batch processing for maximum throughput

AutoTrim

Automated Trimlines. Zero Manual Setup.

Effortless Aligner Separation

Designed for speed, safety and repeatability.

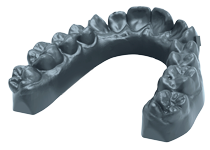

Thermoformed clear aligners often adhere tightly to the model.

DMU Separators enable fast, safe and non-destructive removal — designed for reliable daily use.

Find the separator that fits your workflow.

Separator - Pin Over Bar

For high-volume automation

Uses an integrated support bar in the printed model for fast, repeatable separation.

Uses an integrated support bar in the printed model for fast, repeatable separation.

Fully automated when combined with AutoTrim — ideal for high-throughput aligner production.

Separator - Standard

For maximum flexibility

Integrates seamlessly into existing aligner workflows using vacuum disc and filament separation. A reliable solution without modifying your current setup.

LAC – Laser Aligner Cutter

Fully Automated Laser Cutting for Clear Aligners

The LAC delivers precise, clean laser cutting without any post-processing — designed for high-throughput aligner production.

Combined with AutoTrim, the LAC automatically assigns the correct cutting file using optical ID recognition. No manual file selection. No guesswork. Just load the aligner and remove the finished part.

Built for speed, consistency and seamless integration into a fully digital aligner workflow.

“All you do is remove the finished aligner — every minute.”

LAC - Suction Unit

Engineered for the LAC. Essential for cutting quality.

Optimized airflow and integrated filter monitoring ensure clean edges and stable cutting results throughout continuous operation.

Fully integrated and automatically controlled via the LAC system.

Product Preview

Your On-Site Aligner Factory

A compact, all-in-one system for fast, efficient and fully automated aligner production.

Introducing the Clear Aligner Automat (CAA) — a world-first innovation that integrates the entire aligner manufacturing process into a single, compact system.

Designed for on-site production, the CAA enables dental labs and clinics to manufacture aligners faster, more efficiently and with consistent, high-quality results.

Interested? Sign up to receive exclusive product updates.

Service & Supplies

Everything you need to keep your systems running at peak performance.

From consumables and spare parts to service subscriptions — discover solutions designed for reliability, uptime and long-term efficiency across your DMU systems.

Questions? We’re here to help.

Whether you’re looking for more details, a personalized demo or a tailored offer — our team is happy to support you.