Separator - Standard

Reliable aligner separation for flexible daily workflows.

Thermoformed clear aligners often adhere tightly to the model. The Separator – Standard enables safe, controlled and non-destructive removal — designed for reliable daily use in labs and clinics.

Non-Destructive Removal

Aligners are separated safely without damaging the model or material.

Flexible Operation

Compatible with various thermoforming setups and workflows.

Controlled Separation

Manual vacuum control enables precise handling.

Daily Reliability

Designed for consistent results in everyday production.

Product Overview

The Separator – Standard is a manual separation device designed to remove thermoformed clear aligners safely and efficiently from the model.

Using controlled vacuum and mechanical separation, the system allows precise handling during the separation process. This makes it ideal for flexible workflows, smaller batch sizes, and environments where adaptability is required.

The Separator – Standard integrates seamlessly into existing aligner production setups without the need for automation or workflow modifications.

Feature Highlights

Vacuum Separation

- Manual vacuum control

- Precise handling during separation

- Reduced risk of material damage

Flexible Compatibility

- Works with common thermoforming devices

- Adaptable to different aligner geometries

- No workflow restructuring required

Safe Model Handling

- Non-destructive separation process

- Protects printed or milled models

- Reliable results with repeated use

Simple & Robust Design

- Compact mechanical system

- Minimal maintenance

- Designed for daily lab operation

How it works

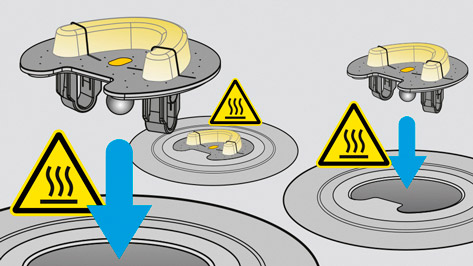

The separation process is performed step by step using controlled vacuum and mechanical assistance.

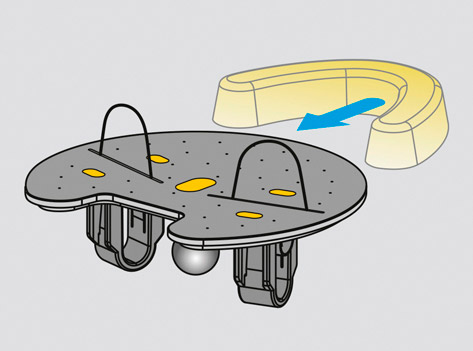

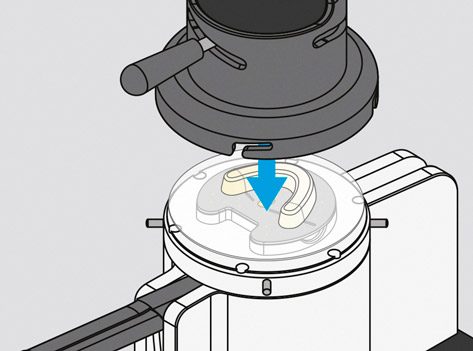

01

Place the tooth model onto the vacuum disc beneath the separation threads and secure it in position.

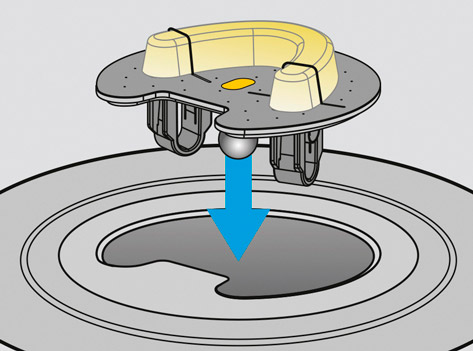

02

Insert the vacuum disc into the thermoforming unit using the adapter ring suitable for your device.

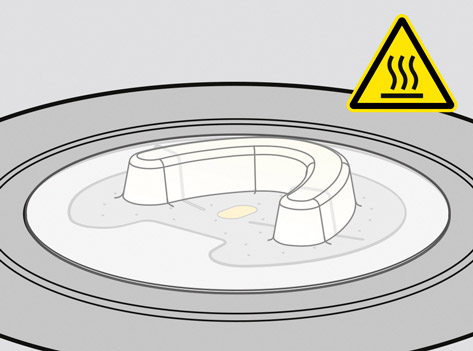

03

Thermoforming: Insert the aligner foil into the thermoforming unit and thermoform the tooth model.

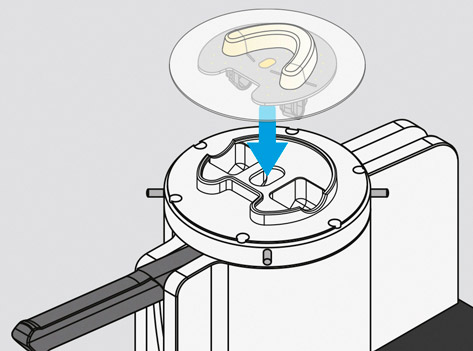

04

After thermoforming, place the thermoformed tooth model with the vacuum disc into the separator.

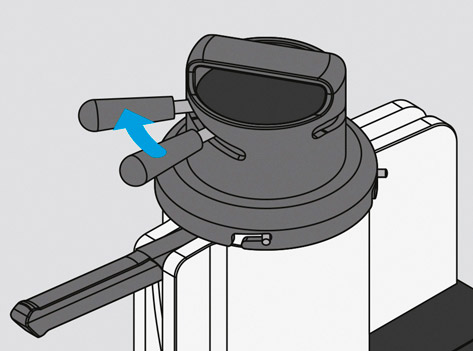

05

Place the vacuum lid onto the separator and secure it with a rotary motion.

06

Use the lever to generate a vacuum, which is applied as counterpressure.

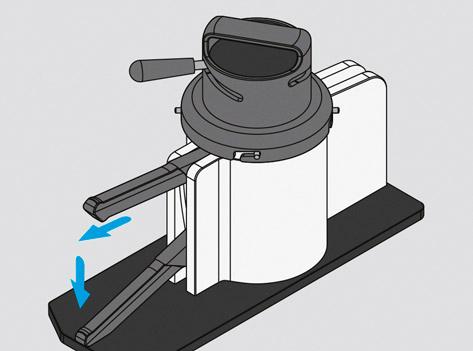

07

Pull the lever towards you and downward to separate the tooth model from the aligner foil.

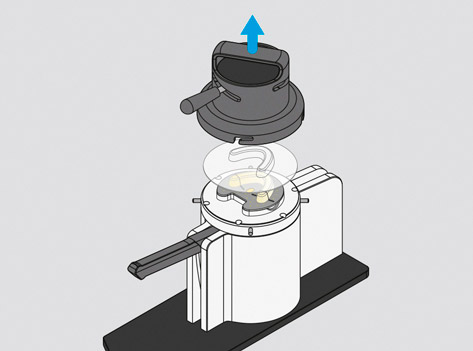

08

Unlock and remove the vacuum lid. The separated aligner is now ready for further processing.

Adapters for Separator - Standard

Adapters are available in different sizes depending on the thermoforming device and manufacturer. Please select the appropriate adapter for your setup.

Erkodent Erkoform ™

#100902

Erkodent Erkopress Motion ™

#102203

Barth Medical® B-Form

#101854

Set - Scheu Ministar ™

#103509

Set - Scheu Biostar ™

#103517

Dreve Dentamid Drufomat Scan

#101871

Aixin AX-PMU4

#102020

Spare Parts & Consumables

Selected components and consumables are available to ensure reliable operation and long-term use of the Separator – Standard.

Separating threads [Set of 10 pairs]

#101235

Vacuum Disc [without threads]

#100751

Use a second vacuum disc to place the next model while the thermoforming machine is working on the already inserted model.

You can also produce simultaneously by using more vacuum discs (not included) and by equipping additional thermoforming units with adaptors.

When Separator – Standard Is the Right Choice

The Separator – Standard is designed for flexible, manually controlled aligner separation and is well suited for variable workflows and smaller batch sizes.

For faster, more repeatable separation without separating threads, the Separator – Pin Over Bar offers a streamlined alternative.

Technical Specifications

Key technical parameters for system integration and operation.

Key Technical Parameters

ALIGNER SEPARATION

Process time (per aligner separation)

Aligner foil diameter

Aligner foil height

approx. 20–35 s

Ø120–125 mm

0.25–1.0 mm

GENERAL

W / L / H

Weight

145 × 385 × 215 mm

4 kg

Frequently Asked Questions

Clear answers to common questions about separator operation, compatibility and daily use.

No.

The Separator – Standard is a manually operated device designed for controlled, non-destructive aligner separation.

The Separator – Standard is designed for flexible, manual workflows.

The PinOverBar version is optimized for automated, high-volume production environments.

The Separator – Standard is compatible with common thermoforming devices.

Adapters are available in different sizes depending on the manufacturer and model.

No.

The Separator – Standard operates using vacuum and mechanical assistance and does not require compressed air.

When used as intended, the separation process is non-destructive and designed to protect both the aligner and the model.

Yes.

The device is designed for reliable daily operation in dental labs and clinical environments.

Looking to integrate a separator into your workflow?

Whether you are setting up a new aligner production process or optimizing an existing workflow, our team is happy to support you with separator selection, compatibility checks and configuration advice.

Our team will respond personally and help you find the right configuration.