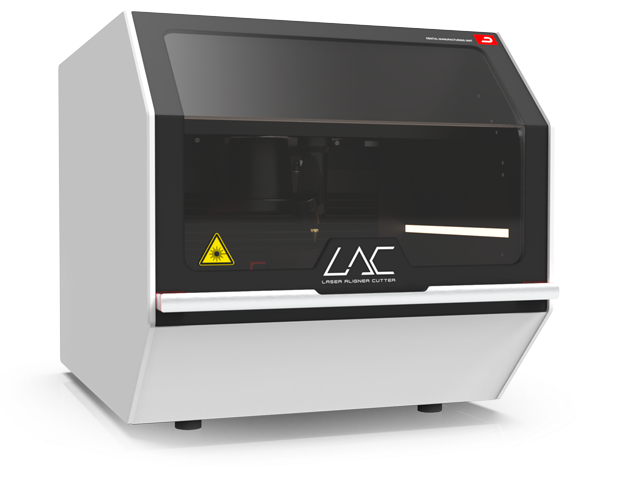

Precision Laser Cutting for Clear Aligners

Automated trimming with consistent quality — built for professional aligner production.

Automated trimming with consistent quality — built for professional aligner production.

The LAC Laser Aligner Cutter delivers clean, sealed edges without post-processing. Designed for high-throughput labs and clinics that demand speed, reliability, and repeatability.

Perfectly Clean Edges

Laser technology produces smooth, sealed trim edges without burns or material stress.

Up to 7× Faster Trimming

Accelerate your aligner production workflow through automated laser cutting.

No Tool Wear

No blades, no mechanical wear — consistent results over time.

Consistent & Repeatable

Every aligner trimmed with identical precision, from first to last.

Product Overview

The LAC Laser Aligner Cutter is a high-precision laser system designed to automate the trimming of clear aligners.

By replacing mechanical cutting with laser technology, the LAC ensures consistently clean trim edges while significantly reducing manual handling and post-processing.

Combined with AutoTrim, the system automatically assigns the correct trimming file based on optical ID detection during alignment.

Built for high-throughput environments, the LAC integrates seamlessly into a fully digital aligner manufacturing workflow.

Feature Highlights

Quality

- Industrial-grade components

- Stable cutting performance over long production cycles

- Minimal maintenance required

Performance

- High-speed laser cutting for rapid turnaround

- Smooth, sealed trim edges

- No heat distortion of the aligner material

Compatibility

- Works with common aligner materials

- Suitable for thermoformed and 3D-printed aligners

- Integrates seamlessly into lab and clinic workflows

Automation

- Automatic file assignment via optical ID recognition

- Optional laser-based identification marking

- Minimal user interaction

- Ready for continuous, high-volume operation

How it Works

The LAC adapts to your workflow — from manual file selection to fully automated trimming with AutoTrim. Choose the level of automation that fits your production setup.

Standard Workflow

- Load the aligner into the LAC.

- Select the corresponding trimming file at the web-interface.

- The camera system automatically determines the correct cutting position.

- The LAC performs precise laser cutting.

- Optional laser-based identification marking can be applied.

- Remove the finished aligner — ready for use.

Reliable trimming for flexible and established production setups.

Automated Workflow (AutoTrim)

- Load the aligner into the LAC.

- AutoTrim provides ID-linked trimming data for the aligner.

- The camera system automatically determines the correct cutting position and detects the optical ID.

- The correct trimming file is selected automatically.

- The LAC performs precise laser cutting.

- Optional laser-based identification marking can be applied.

- Remove the finished aligner — ready for use.

Recommended for high-volume production — maximum automation. No manual file selection. Reduced risk of errors.

Built for scale.

When combined with AutoTrim, the LAC becomes part of a fully automated aligner production system.

The Complete Aligner Trimming Workflow

A coordinated system designed for speed, consistency and scalable aligner production.

The Ultimate Production Bundle combines AutoTrim, the LAC Laser Aligner Cutter, the Separator and the LAC Suction Unit into a fully integrated trimming workflow.

Each component is designed to work seamlessly with the others — reducing manual handling, minimizing errors and ensuring consistently high-quality results across the entire production process.

- AutoTrim – Automated trimline generation and ID-enabled workflow

- LAC – Precision laser cutting with consistent, sealed edges

- Separator – Safe and repeatable aligner removal from the model

- LAC Suction Unit – Integrated extraction for stable cutting quality

From trimline generation to finished aligner — optimized as one system.

Supporting components and proven performance complete the system.

LAC - Suction Unit

Engineered for the LAC. Essential for consistent cutting quality.

Engineered for the LAC. Essential for consistent cutting quality.

Optimized airflow and integrated filter monitoring ensure clean edges and stable cutting results throughout continuous operation.

Fully integrated and automatically controlled via the LAC system.

WIKARUS – Business Award for Innovation

The LAC Laser Aligner Cutter was awarded the WIKARUS Business Award for Innovation.

The award recognizes innovative industrial solutions with a strong impact on real-world production workflows.

Dental Manufacturing Unit received the WIKARUS trophy and first place at the WIKARUS 2022 Business Award for Innovation.

Technical Specifications

System Overview

- Laser-based cutting system for clear aligners

- Designed for continuous operation in dental labs and orthodontic clinics

- Autonomous operation after job start

Cutting Technology

- Laser trimming with sealed, smooth edges

- No mechanical cutting tools

- No tool wear

- No post-processing required

Camera & Alignment System

- Integrated camera system for aligner positioning

- Automatic detection of the correct cutting start point

- Optical detection of ID markers (if present)

Automation & Workflow

- Standard Workflow with manual file selection

- Automatic trimming file assignment based on optical ID detection during alignment

- Optional laser-based identification marking derived from trimming data

Input Data

- 3D aligner model files (STL)

- Trimming path files (PTS)

- Data provided via shared folder (local or network-based)

Supports standard 3D model and trimming path file formats.

Identification & Marking

- Optional laser-based marking during trimming

- Supports alphanumeric identifiers for marking (e.g. case ID, batch number, upper/lower)

- Responsibility for marking usage and content lies with the operator

Operation

- Minimal operator interaction

- Intuitive workflow

- Designed for high-throughput production environments

System Integration

- Compatible with common aligner materials

- Seamless integration into digital aligner manufacturing workflows such as Dental Axess (Xflow/Xplan) and Arcadlab

- Data compatibility to all major vendors like 3Shape, OnyxCeph or ORTH'UP.

Maintenance

- Low-maintenance design

- No consumable cutting tools

- Stable performance over long production cycles

Key Technical Parameters

ALIGNER

Process time

(aligner cut)

Aligner foil diameter

Aligner foil height

Repeat accuracy

approx. 60-90 s

Ø120-125 mm

0.25-1 mm

±0.1mm

LASER

Laser type

Laser power

Wavelength

Laser class product

Cooling

CO₂

20 W

9.3 µm

Class 1

Air-cooled

SUCTION UNIT (requirements)

Connection diameter

Air flow rate (unimp.)

Filters

ø50 mm

240 m³/h

• Prefilter (G4)

• HEPA filter (H13)

• Activated carbon filter

INTERFACES

Hardware Interface

Software Interface

Gigabit Ethernet

(IEEE 802.3)

Import of standard aligner data (STL models and trimming paths as PTS, CSV, or XYZ files)

POWER

Voltage

Power consumption

Single-phase

110–230 V, 50/60 Hz

900 W

GENERAL

W / L / H

H (opened)

Noise level

620 × 880 × 640 mm

980 mm

65 dB(A)

Specifications may vary depending on configuration and regional requirements.

Dimensions & Machine Views

Service, Support & Updates

Built for reliable daily operation

The LAC is designed for continuous use in professional production environments. DMU supports this with structured service options, software updates and long-term system support — ensuring stable performance throughout the system’s lifecycle.

Service & Support

- Professional onboarding and system setup

- Remote support and diagnostics

- Preventive maintenance recommendations

- Access to DMU technical support specialists

Support services are designed to minimize downtime and ensure reliable daily operation.

Software Updates

- Regular software improvements and optimizations

- Compatibility updates for evolving production workflows

- Continuous refinement of system stability and performance

Software updates ensure that the LAC remains aligned with current production requirements over time.

Service Subscription

For customers requiring extended support and predictable operating costs, DMU offers optional service subscription models.

Depending on configuration, these may include: Priority technical support, Extended update access, Preventive service planning

DMU systems are developed with a long-term perspective — combining precision engineering, software intelligence and reliable service.

Frequently Asked Questions

Clear answers to common questions about the LAC system, workflows and operation.

The LAC is compatible with commonly used clear aligner materials. Specific material compatibility may vary depending on formulation and thickness.

No.

The laser cutting process produces clean, sealed trim edges, eliminating the need for additional post-processing.

The LAC processes standard 3D aligner model files and corresponding trimming path files provided via the system’s shared folder (local or network-based).

Yes.

The LAC supports a standard workflow with manual trimming file selection, as well as a fully automated workflow when combined with AutoTrim.

Yes.

AutoTrim prepares ID-linked trimming data for the aligner.

During alignment, the LAC detects the optical ID and automatically selects the correct trimming file before cutting.

Yes.

The LAC supports optional laser-based identification marking during the trimming process.

Marking content is derived from trimming data and may include alphanumeric identifiers such as case or batch numbers.

The use and content of markings are the responsibility of the operator.

No.

The LAC operates exclusively on production data provided by the operator and does not manage patient information.

Yes.

The system is designed for continuous operation and reliable performance in high-throughput production environments.

DMU provides professional onboarding, technical support and structured service options to ensure reliable daily operation.

Yes.

The LAC is designed with a modular architecture that supports future software and workflow enhancements.

Ready to integrate LAC into your workflow?

Whether you are planning a new production setup or looking to optimize an existing workflow, our team is happy to support you with detailed information, demonstrations and configuration advice.

Our team will respond personally and help you find the right configuration.