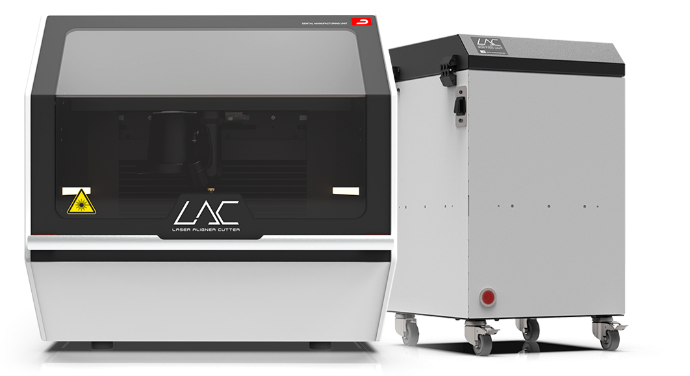

LAC – Suction Unit

Engineered for the LAC. Essential for cutting quality and a clean working environment.

To ensure stable cutting results and a safe production environment, the LAC Suction Unit is specifically designed to match the LAC Laser Aligner Cutter. Fully integrated, automatically controlled and optimized for continuous operation.

Clean Environment

Efficient extraction of fumes and particles during laser cutting.

Stable Cutting Quality

Optimized airflow ensures consistent cutting results.

Fully Integrated Control

Automatically controlled via the LAC system.

Industrial Filtration

Multi-stage filter system for reliable daily operation.

Product Overview

The LAC Suction Unit ensures optimal airflow during laser cutting — a key requirement for clean edges and stable cutting quality.

Equipped with a multi-stage filtration system, including a prefilter (G4), HEPA filter (H13), and activated carbon filter, the unit efficiently captures particles and emissions generated during the cutting process.

Designed specifically for use with the LAC Laser Aligner Cutter, the suction unit is fully integrated and automatically activated as soon as cutting begins — ensuring seamless and efficient operation without manual intervention.

Feature Highlights

Optimized Airflow

- Designed to match the LAC cutting chamber

- Ensures stable cutting conditions

- Supports consistent edge quality

Multi-Stage Filtration

- Prefilter (G4)

- HEPA filter (H13)

- Activated carbon filter

Integrated System Control

- Automatically activated by the LAC

- No separate operation required

- Seamless workflow integration

Built for Continuous Operation

- Industrial-grade components

- Designed for daily production use

- Reliable performance over long cycles

How it Works

The LAC Suction Unit operates fully automatically as part of the LAC cutting process.

Steps

- The aligner cutting process is started on the LAC.

- The suction unit is activated automatically.

- Airflow and filtration ensure clean and stable cutting conditions.

- Filter status can be monitored to maintain optimal performance.

Part of the Complete LAC Workflow

Combined with the LAC Laser Aligner Cutter, the Suction Unit becomes an integral part of a coordinated aligner trimming system — designed for quality, safety and scalable production.

Combined with the LAC Laser Aligner Cutter, the Suction Unit becomes an integral part of a coordinated aligner trimming system — designed for quality, safety and scalable production.

Technical Specifications

Key technical parameters for system integration and installation planning.

Key Technical Parameters

SUCTION UNIT

Connection diameter

Air flow rate (unimp.)

Filters

ø50 mm

240 m³/h

• Prefilter (G4)

• HEPA filter (H13)

• Activated carbon filter

POWER

Voltage

Power consumption

Single-phase

110-230 V, 50/60 Hz

700 W

GENERAL

W / L / H

Weight

Noise level

390 × 430 × 630 mm

35 kg

56 dB(A)

Specifications may vary depending on configuration and regional requirements.

Frequently Asked Questions

Clear answers to common questions about operation, filtration and integration.

Recommended.

The LAC Suction Unit is engineered as the integrated extraction solution for the LAC system to ensure stable cutting quality and a safe working environment.

The LAC can also be connected to an existing extraction system, provided it meets the required specifications (e.g. airflow rate and connection diameter).

For best performance and seamless integration, DMU recommends the LAC Suction Unit.

No.

The suction unit is fully integrated and automatically controlled by the LAC system. It activates automatically when the cutting process starts.

The system uses a multi-stage filtration setup consisting of:

- Prefilter (G4)

- HEPA filter (H13)

- Activated carbon filter

This combination effectively captures particles and emissions generated during laser cutting.

Yes.

Stable airflow is essential for consistent laser cutting results. The suction unit ensures clean cutting conditions and supports consistent edge quality.

No.

The LAC Suction Unit is specifically engineered to match the LAC Laser Aligner Cutter and is not intended for use with other systems.

Filter status can be monitored to ensure optimal performance.

Specific maintenance intervals depend on usage and operating conditions.

Yes.

The system is designed for daily use in professional production environments and supports continuous operation.

The integrated filtration system helps reduce emissions and odors generated during the laser cutting process, contributing to a cleaner working environment.

No.

The suction unit is designed for straightforward installation and seamless integration with the LAC system.

Ready to complete your LAC setup?

Whether you are planning a new installation or optimizing an existing LAC system, our team is happy to support you with configuration details, system requirements and integration advice.

Our team will respond personally and help you find the right configuration.